Single and multi-start dressing of worm grinding wheels in continuous generating grinding with various tool concepts.

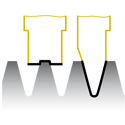

MIRA DDS Single taper dressing discs

The tools are always employed in pairs. They are manufactured using a positive electroplating process. Rework is possible by stripping and replating. These tools are primarily used for small and medium batch sizes and offer users the most flexibility.

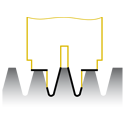

MIRA DDS Full profile roller (single profile)

The tools can be used in pairs. They are manufactured using a positive electroplating process. Rework is possible by stripping and replating. These tools are primarily used in medium and large batch sizes and offer the user some flexibility. This tool concept is a good option when grinding the root form of the tooth.

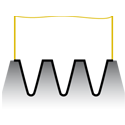

These tools have multiple profile ribs/rows. They are manufactured using a reverse electroplating process. A considerable reduction of the dressing times can be achieved, and the same gear quality can be produced as with positive electroplated profile dressing tools. Due to the advantages of the reverse plating process the tool life is significantly higher than with positive electroplated tools.

The set profile roller is a multi-part tool that is delivered assembled and matched precisely to user requirements. They are manufactured using a positive electroplating process. Worn tools can be reworked by stripping and replating. The tools are used for medium and large batch sizes. Set-up times are minimized allowing for high productivity.