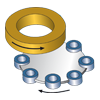

Different face grinding methods are used for rational production of functional surfaces with high requirements relating to evenness, plane parallelism and surface finish.

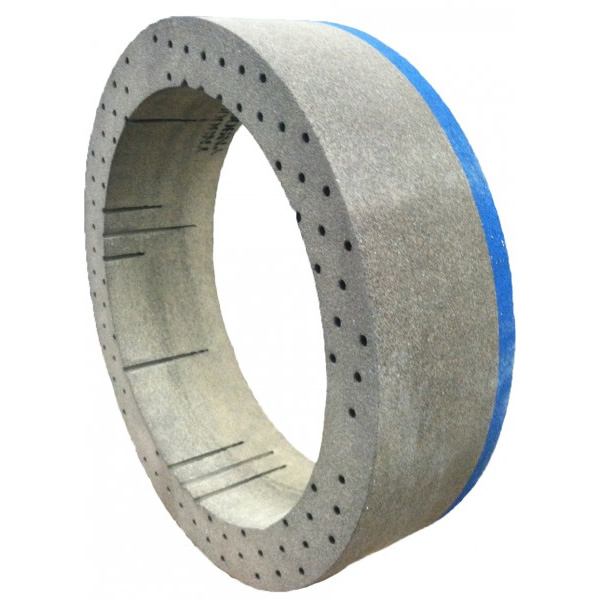

Either both faces are machined simultaneously (double side face grinding) or only one face is machined using single wheels, segments, rings or cups. The components are often manufactured in mass production, which means that there are high requirements with respect to process stability.

The nature of the process means that there are large contact areas and long grain contact paths, leading to low forces on individual grains. The result of this is increased generation of heat and this must be counteracted by intelligent tool concepts. These varying requirements are adapted to the respective application through use of different technologies.

RADIAC offers the solution.